Chemical Solution Preparation Facilities

We produce chemical solutions of coagulants, flocculants and other solutions for process purposes. These stations are automated. They don’t require staff servicing, except for a new tank’s loading and installation as well as control of the tank’s operation.

There are three types of preparation facilities:

|

|

Facilities for preparation of powder solutions;

|

|

|

Facilities for preparation of concentrated solutions;

|

|

|

Facilities for preparation of power and concentrated solutions.

|

Our facilities are divided in one-, two- and three-chambered facilities:

|

|

One-chambered facilities are the most simple and reliable for the preparation of different chemical solutions. They are used as a component of complex systems and other technical processes. They consist of the tank (which is made of polymeric material and serves as a preparation chamber), an electrical mixing machine, dosing pump and the automated unit for process control. One-chambered chemical solution preparation facilities have a volume ranging from 100 litres to 1m3 of the final solution.

|

|

|

Two-chambered facilities are used for the preparation of coagulant solutions. Mixing and preparation of the coagulant solution takes place in the first chamber, situated inside the second o main chamber. They are assembled from the first chamber (prime product filled there), the second chamber (for solution mixing and preparation), an electrical mixing machine (s), dosing pump (s), an automated unit for process control, shut-off valve, process control instruments and if necessary a pulsation damper. Two-chambered chemical solution preparation facilities have a volume ranging from 1m3 to 10m3. They are usually made of polymeric material with an external stainless steel frame.

|

|

|

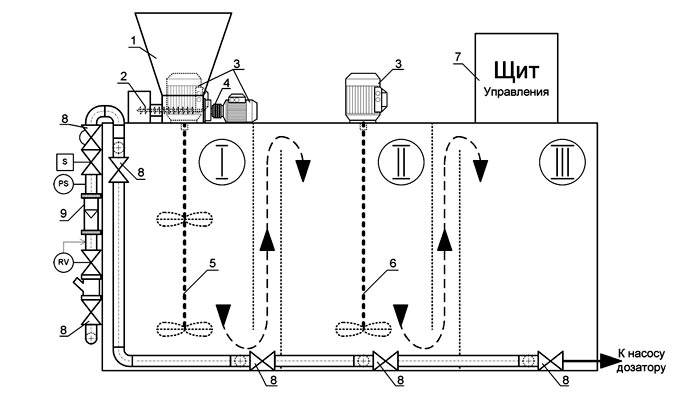

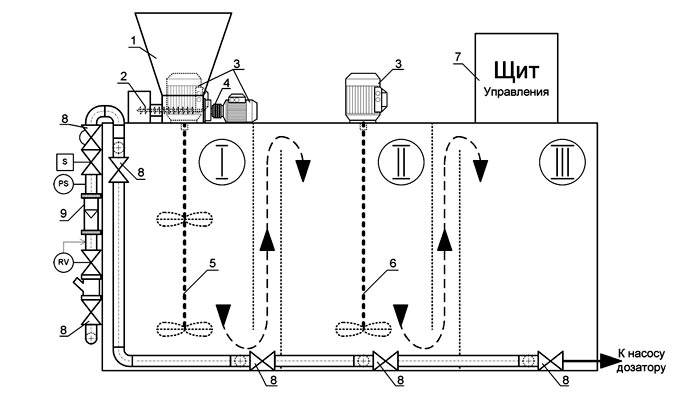

Three-chambered facilities are used in the preparation of flocculant solutions of granular powder. They contain the first chamber for initial mixing of the product; the second chamber for aging; the third chamber for output into the dosing line. The second chamber is also equipped with a mixing machine. The three-chambered chemical solution preparation facility is the most complex and it has two modifications: 1) all three chambers are made of stainless steel; 2) all three chambers are made of polypropylene with external stainless steel frames.

|

These sections consist of a loading unit (1) which is equipped with a worm mechanism (2), the engine (3) and gear set (4); the first, second and third preparation chambers have mixing machines (5;6); a dosing pump (s), an automated unit (7) for process control; shut off valve (8) and process control instruments (9). Automation is realized on the controller. One section’s productivity is from 500 to 8000 l/h.

To choose the equipment, please complete the questionnaire or contact us.

|